User:Benatar.1/WE7406 Article 14

Expand/Improve Article on Radio-Frequency Welding

[edit]Compare with current Wikipedia article on Radio-frequency_welding

NOTES: This article is already published. Anything I added is in [bold and bracketed]. Anything I am deleting is lined out. I tried to avoid minor style changes. Most deletions are because information is uncited and contradicts something else in one of my references.

Radio-frequency welding, also known as dielectric weldingand high-frequency welding, is a plastics joining [added plastic joining link] process that utilizes [very] high-frequency [electric fields to induce heating and melting of thermoplastics to be joined.[1]]radio waves to heat plastic parts to the point they form a melt layer. After the development of the melt layer, the parts are pressed together and then allowed to cool causing fusion. This process is capable of producing high quality joints in a range of plastics. [The electric field is applied by a pair of electrodes after the parts being joined are clamped together. The clamping force is maintained until the joint solidifies.] Advantages of this process are fast cycle times [(on the order of a few seconds), automation, repeatability] easily automated, repeatable, and good weld appearance. While this process has some great advantages, there are some limitations. Only plastics which have dipoles can be heated using radio waves and therefore not all plastics are able to be welded using this process. Also, this process is not well suited for thick or overly complex joints. The most common use of this process is lap joints or seals on thin plastic sheets or parts.

Heating mechanism

[edit]

The heating mechanism in Radio Frequency plastic welding is dielectric heating. When an electric field is applied to a dipole molecule [with an asymmetric distribution of charge, or polar molecule], the [electric forces]polarity of the molecule will cause [the molecule]it to align itself with the electrical field.[1] When an alternating electrical field is applied, the molecule will continuously [reverse its alignment,]try to align itself with the alternating electrical field leading to molecular rotation. This process is not instantaneous therefore if the frequency is high enough, the dipole will be unable to rotate quickly enough to stay aligned with the electrical field resulting in random motion as the molecule attempts to follow the electrical field. This motion causes intermolecular friction which leads to heat generation.[2] [The amount of heat generated by friction in the material is dependent on field strength, frequency, dipole strength, and free volume in the material.[1]] Since the main driving force for dielectric heating is the interaction of the dipole of a molecule with the applied electrical field, RF welding can only be conducted on dipole molecules. The typical frequency range for dielectric heating is 10-100 MHz but normally RF Welding is conducted around 27 MHz.[2]At too low of frequency, the dipoles are able to align themselves with the electrical field and stay in phase with the electrical current minimizing the intermolecular friction that is produced. This can also be described as having minimal power loss from the electrical field since the molecules will stay in phase and absorb minimal energy. As frequencies become high enough, power loss starts to increase as the dipoles are unable to align themselves at the rate of the reversing electrical field. The dipoles become out of phase absorbing energy and this is when heating occurs. At a certain frequency, a power loss maximum is reached to where higher frequencies will have decreased power loss and produce less heating. The maximum dielectric power loss is material dependent.[3]

Compatible materials

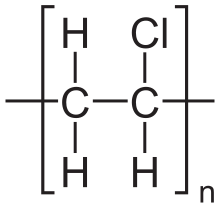

[edit]The Radio Frequency heating mechanism relies on a dipole in the molecule in order to generate heat and therefore the plastics used in RF Welding are limited to those whose molecules contain an electrical dipole.[4] Permanent molecular dipoles can form due to differences in electron densities [electronegativities] between the atoms of a molecule. [Negative charge is shifted toward atoms with higher electronegativity, resulting in more negatively charged regions surrounding more electronegative atoms, and positively charged regions surrounding less electronegative atoms.][1] This can leave regions of negative charge where electron densities are high and positive charge where electron densities are low. A simple example of this is a water molecule where the high electronegativity of Oxygen creates a negative pole by the Oxygen atom and a positive pole by the Hydrogen atoms. [Because polyethylene consists of symmetric mer groups, no dipole forms, and polyethylene cannot be joined using radio-frequency welding. Like water, polyvinyl chloride (PVC) consists of asymmetrically distributed atoms of differing electronegativities, with a resulting dipole moment. Because of its strong dipolar moment (and other properties) PVC is considered an excellent material for radio-frequency welding. Using this same principal when analyzing a (C2H3Cl)nPVCmolecule, a higher electron density would exist near the Cl atom in each unit of its polymer chain leading to a non-uniform distribution of charges and therefore a dipole would exist in PVC molecules. This makes PVC compatible for RF Welding. It is possible to weld non-polar plastics by [adding a third member to the joint to improve dielectric loss.][1]using a conductive-composite implant.[Other properties that contribute to good radio-frequency weldability are high dielectric constant, which reduces resistance to current flow, and high dielectric strength, which prevent arcing through the joint members during welding. Reducing resistance in the joint allows heat to be generated at lower electrode voltages. Arcing is undesirable as it would damage teh parts and equipment.][1] Other plastics commonly RF Welded include PET, nylons, thermoplastic polyurethanes, cellulose acetate, EVA, and PVDC.[2]

[Some plastics commonly welded with dielectric heating include:[1][2]

- Polyvinyl chloride (PVC)

- Chlorinated polyvinyl chloride (CPVC)

- Polyurethane

- Nylons

- Cellulose acetate

- Ethylene-vinyl acetate (EVA)

- Polyvinylidene chloride (PVDC)

]

Procedure and process

[edit]The RF Welding procedure [consists of five steps:[1]

- Loading parts

- Applying pressure

- Applying electric field

- Holding pressure

- Unloading parts

can be broken down into three main parts. [Loading consists of placing the joint member into the welding machine. The welding operation begins with application of pressure on the members from the electrodes. Generally, the bottom electrode is fixed, and and actuator drives the upper electrode down with a prescribed force. The electric field is applied to the parts for a specified time while pressure from the electrodes is maintained. Dielectric heating causes the parts that are in intimate contact to melt, and the liquid polymers diffuse into each other at the interface. Diffusion and solidification of the joint occur while pressure is maintained for a specified time. Once the joint is cooled and the upper electrode is retracted, the part can be unloaded.][1] eBefore the start of the procedure, proper part alignment is necessary. The first stage of the procedure is the pre-welding time which is used to reach the optimal pressure for welding. Arcing or material flashing and burning is possible if power is applied before the desired pressure is reached. This is similar to the first step in resistance spot weldingof metals where a clamping time is used to ensure the desired force is reached before current is applied to avoid arcing. The second part of the procedure is when RF energy is applied to induce the dielectric heating mechanism in order to heat the joint to the melting temperature leading to fusion. At a certain point during heating, an equilibrium state can be reached when the heat generated from the applied power is equal to the heat loss through the dies used for clamping. Thinner parts will have more heat loss through the dies than thicker parts and different materials are more responsive to the dielectric heating mechanism than others. Therefore, the power used for welding must be tailored to the material that is being welded and the thickness of the joint in order to reach a heating equilibrium at the desired temperature. The final part of the procedure is the cooling stage which is the time allowed for the part to cool before removing the pressure applied from the dies. Some of the key process parameters are the clamping force, RF power, heating time, cooling time, and electrode or platen temperature (electrode and lower platen can heat up after performing many welds in a row which can impact the other parameters).

[The parameters used to control the welding process consist of:[1]

- Weld time

- Power output

- Clamp pressure

- Hold time

Add detailed information about parameters...Other procedure elements that effect weld performance include generator tuning (capacitance and inductance), external cooling, fixture alignment, buffer material.[1]

Welding equipment

[edit]There are six major parts of RF Welding machines. [Sources vary slightly on grouping of radio-frequency welding equipment, but generally they consist of]They are the RF power generator, control unit, press, enclosure, [electrodes, and sometimes a] handling mechanism, and electrode.[1][2]The RF power generator is what supplies the power to be used for welding.[converts line power to VHF, high-voltage power for welding. Typical voltages are 1kVAC - 1.5kVAC at a frequency of 27.12 MHz.][1] The power needed for welding is based on the area of the weld, thickness, and the material. The control unit is the system used for operating the machine. The control unit is responsible for processing the information on the desired welding inputs such as force, power, and heating time, and instructing the other components of the machine to satisfy these process parameters. [Some controllers are capable of monitoring outputs and adjusting parameters to ensure satisfactory welding.][1] The press [(or actuator)] is what supplies the force to the joint that is to be welded. These are most commonly pneumatic but can also be hydraulic for larger scale applications. {NEED A REFERENCE} The electrode[s are a pair of conductive structures that transmit the electric field through the members being joined. The electrodes contact the parts and apply the hold pressure prior to and during welding, and through solidification. Generally, the upper electrode projects from the upper fixture surface, while the lower electrode is a flat conductive surface. In some cases, the bottom electrode can project above the bottom fixture, to conform to geometry or to better localize melting through the reduction of stray electric field. Both electrodes can be fabricated with features to alter the finish of the welded surface.] is responsible for pressing the parts together using the force supplied by the press and transferring the RF energy into the joint. They are usually made of either brass, copper, or bronze.[1] An RF enclosure or a cage that goes around the electrodes and open areas is used to protect the operator from injury [including radio frequency radiation.][1]and from the high voltages emitted from the electrodes. [Automated machines include a] The handling mechanism is used to transport the plastic parts to and from the RF Welding machine. It also is responsible for properly placing and aligning the parts under the electrodes. An additional optional component of an RF Welding system is a barrier material that can be used and placed between the parts to be welded and the lower platen in order to reduce the risk of arcing and reduce the heat loss from the joint.[2]

Applications

[edit]The most common application for RF Welding is sealing thin sheets of [polar thermoplastics.]plastic such as PVC. Some products that typically use RF Welding include beach balls, airbeds, life jackets, book covers, and loose-leaf binders. RF Welding is also commonly used for medical items such as blood bags, disposable clothing, blood pressure cuffs, and packaging for certain items.[2]It can be seen through the common applications of RF Welding that it is designed primarily for the welding or sealing of thin sheets so they are leak free.

[Microwave welding

[edit]Microwave welding is a subset of radio-frequency welding that is executed with an electric field operated in the microwave region of the spectrum (300MHZ to 300GHz).[1]

Microwave welding uses non-conductive clamps, power is emitted from a magnetron.[1]

Microwave welding is capable of welding non-polar plastics as well as large structures with complicated joints.[1]

Graphite coatings at the interface can be used to facilitate heating of joint members.[5]

]

See also

[edit]References

[edit]- ^ a b c d e f g h i j k l m n o p q r s Plastics and composites welding handbook. Grewell, David A., Benatar, Avraham., Park, Joon Bu. Munich: Hanser Gardener. 2003. ISBN 1569903131. OCLC 51728694.

{{cite book}}: CS1 maint: others (link) - ^ a b c d e f g Troughton, M. J. (2008). Handbook of plastics joining: A practical guide. Norwich, NY: William Andrew.

- ^ Naylon, J., et al. "Efficient microwave heating and dielectric characterization of microfluidic systems." Proceedings of MicroTAS. 2010.

- ^ Leighton, J., Brantley, T., & Szabo, E. (September 01, 1993). RF welding of PVC and other thermoplastic compounds. Journal of Vinyl Technology, 15, 3, 188-192.

- ^ Sun, Xuefei, Wu, Guangming, Yu, Jianxiang, Du, Chunnuan (March 2018). "Efficient microwave welding of polypropylene using graphite coating as primers". Materials Letters. 220: 245–248.

{{cite journal}}: CS1 maint: multiple names: authors list (link)

| This is a user sandbox of Benatar.1. You can use it for testing or practicing edits. This is not the sandbox where you should draft your assigned article for a dashboard.wikiedu.org course. To find the right sandbox for your assignment, visit your Dashboard course page and follow the Sandbox Draft link for your assigned article in the My Articles section. |

#REDIRECT Moving heat source model for thin plates

- From a page move: This is a redirect from a page that has been moved (renamed). This page was kept as a redirect to avoid breaking links, both internal and external, that may have been made to the old page name.